Back in early August, I had the privilege of speaking at USC’s annual BIM Symposium on the topic of visual programming. This post is my attempt at a sort of editorial that follows the narrative of that talk. Along the way, I’ll include a few of the videos that I shared at the presentation which hopefully demonstrate the kind of tool creation I’m talking about. Hope you enjoy.

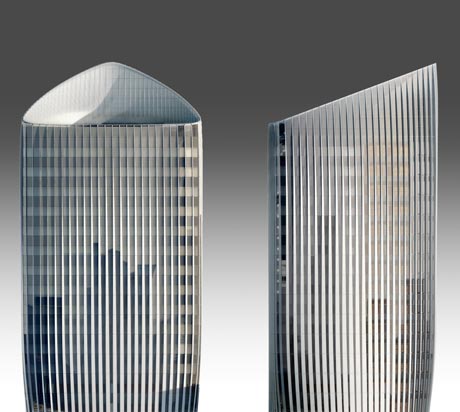

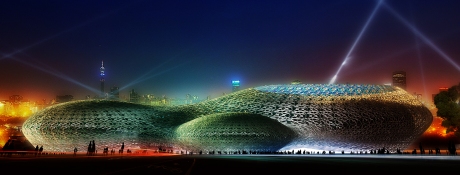

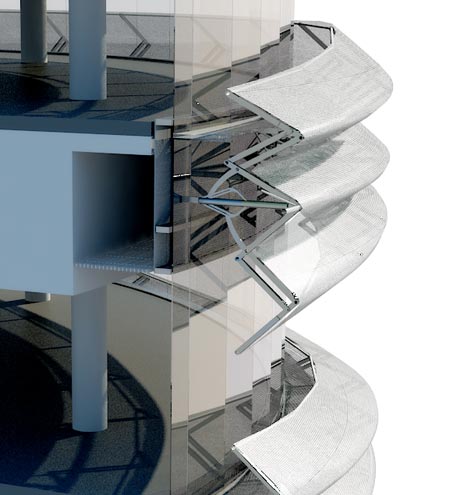

It’s been 5 years since we officially launched our research program at the Yazdani Studio of Cannon Design. During that period we’ve come to understand that the evolution of our process reflects the larger, changing relationship architects have with their means of production. We’ve always been a profession of hackers. Every building is a one-off made up of countless elegant hacks, each bringing disparate materials and systems together into a cohesive whole. But when it comes to the software that designers have come to rely on, most of us have been content with enthusiastic consumerism, eagerly awaiting the next releases from software developers like Autodesk, McNeel and Bentley. In late 2007 something changed. McNeel introduced a visual programming plugin called Grasshopper authored by David Rutten, and more and more architects began to hack their tools as well as their buildings. Read the rest of this entry »